Try GOLD - Free

WHICH CUTTING TOOL WILL PROVIDE THE BEST SOLUTION?

The Machinist

|January 2024

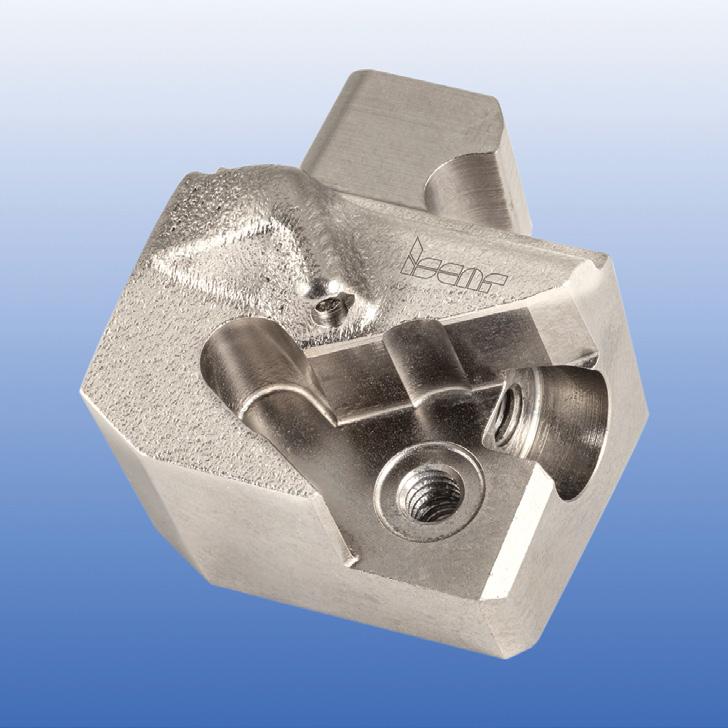

When deciding on the appropriate cutting tool for a particular application, it is difficult to determine whether a standard tool or a special tool is preferable. Here is an insight into ISCAR’s solutions which empower customers to create their own tailor-made tools and overcome manufacturing challenges efficiently.

-

When deciding on the appropriate cutting tool for a particular application, it is difficult to determine whether a standard tool or a special tool is preferable. The ideal tool selection is contingent on various factors, such as the nature of the business situation, the manufacturing programme, the production type, and sometimes personal preferences. Standard cutting tools, produced by a specific tool manufacturer, offer high versatility and are appropriate for machining a diverse range of parts that come in different shapes.

Furthermore, the tool exhibits excellent performance capabilities when cutting various engineering materials. To ensure seamless production processes, it is crucial to have the cutting tools delivered in a timely manner. This is why standard tools are the foundation of tool stock management on metalworking production floors.

A special cutting tool is designed for specific operations on a particular part, made of a specific material, and used on a machine that requires a specific work-holding fixture. This custom-engineered tooling solution aims to provide the best possible performance and outcome. However, there is a downside to this solution as it limits the tool's versatility, making it less adaptable to different applications. As a result, special tools are primarily used for high-volume mass production, especially in the automotive industry.

This story is from the January 2024 edition of The Machinist.

Subscribe to Magzter GOLD to access thousands of curated premium stories, and 10,000+ magazines and newspapers.

Already a subscriber? Sign In

MORE STORIES FROM The Machinist

The Machinist

INDIA'S MANUFACTURING SECTOR BACK IN MOTION

Rising production, renewed investment, and cautious optimism define India's manufacturing landscape as industries rebound from uncertainty and brace for steady growth.

4 mins

November 2025

The Machinist

INDIA'S MINING & CONSTRUCTION EQUIPMENT SECTOR AIMS FOR $45 BILLION BY 2030

As India builds at an unprecedented pace, its mining and construction equipment sector is set to become a global powerhouse by 2030.

4 mins

November 2025

The Machinist

KENNAMETAL UNVEILS ADVANCED MINING TOOLING SOLUTIONS AT IME 2025

At IME 2025 in Kolkata, Kennametal will showcase its latest high-performance tooling and wear-resistant technologies engineered to boost mining productivity, safety, and equipment life.

2 mins

November 2025

The Machinist

CYBER THREATS LEAD MANUFACTURING CONCERNS

A new global survey shows cyber-attacks, environmental pressures, and social issues are now the biggest threats to manufacturing reputation.

3 mins

November 2025

The Machinist

MTX CONNECT JAMSHEDPUR 2025

IMTMA and CII to host the third edition of MTX Connect from November 3-4 at the Cruze Premium Boutique Hotel, Jamshedpur

1 mins

November 2025

The Machinist

INNOVATION TAKES CENTER STAGE AT TECHNOLOGY EVENING IN PUNE

GROB, Kennametal, Renishaw and OPEN MIND Come Together for a Power-Packed Technology Evening in Pune, Showcasing Innovation and Collaboration in Advanced Manufacturing

1 mins

November 2025

The Machinist

IGUS EXPANDS READYCABLE PORTFOLIO WITH NEW CABLES FOR INDUSTRIAL CAMERA TECHNOLOGY

Ready-to-connect, durable and tested cables with Keyence plug-in connectors increase the reliability of vision systems

2 mins

November 2025

The Machinist

EMPOWERING SMART MANUFACTURING

OMRON Automation Center Bengaluru is empowering Indian manufacturers with real-world automation solutions and IT-OT integration to drive MSME growth.

3 mins

November 2025

The Machinist

AUMOVIO TRANSFORMS BENGALURU METRO STRETCH INTO A GREEN CORRIDOR OF ART

AUMOVIO India and Vibhinna India Foundation turn 230 medians and 195 metro pillars into a lush, art-filled urban landmark that blends ecology with culture.

2 mins

November 2025

The Machinist

ROLLS-ROYCE AND BHARAT FORGE STRENGTHEN TIES FOR PEARL 10X ENGINE FAN BLADES

The expanded partnership boosts Rolls-Royce's Make in India vision and cements Bharat Forge's global aerospace manufacturing role.

2 mins

November 2025

Listen

Translate

Change font size