Try GOLD - Free

Beyond Fabs – Building the Infrastructure Backbone of India's Chip Ecosystem

Bisinfotech

|September 2025

India’s semiconductor mission has surged to national prominence in recent years, bolstered by multi-billion-dollar commitments aimed at establishing wafer fabrication (fab) units, compound semiconductor facilities, and chip assembly plants. While the nation rightly celebrates these historic announcements and the construction of state-of-the-art fabs, there remains a critical yet often overlooked pillar underpinning this ambition: the infrastructure and engineering services ecosystem.

-

This ecosystem is what ultimately enables fabs to function reliably, efficiently, and competitively.

As India begins to take its first steps in building a homegrown semiconductor industry, the absence of a mature, end-to-end services ecosystem could become a major bottleneck, unless deliberately addressed.

Beyond Fabs: Building the Fabric That Sustains Them

Setting up a fab is a monumental task, technologically and financially. But constructing cleanrooms and importing advanced tools is only the beginning. The true challenge starts once the lights are turned on. Fab operations require the seamless integration of multiple layers: engineering expertise, installation and commissioning, process optimisation, parts management, diagnostics, maintenance, and most importantly, talent development. Without these layers functioning in unison, even the most advanced fabs risk delays, downtime, and underperformance.

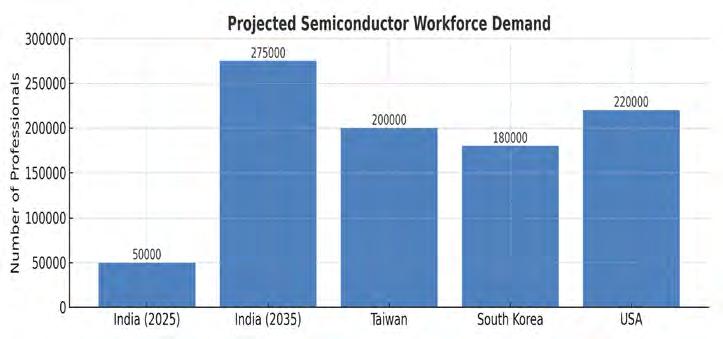

Countries like Taiwan, South Korea, the U.S., and Japan didn't become semiconductor giants by building fabs alone. Their rise was powered by robust ecosystems of service providers, engineering hubs, and training institutions, supporting fabs through every phase of their lifecycle. India, still in the early stages of this journey, must now fast-track the development of its own infrastructure layer if it is to scale globally and sustainably.

End-to-End, Mission-Critical Capabilities

Recognising the urgency, a forward-looking organisation has emerged as a full-spectrum partner for fabs in India. Their comprehensive support spans the entire operational journey, including:

- Tool installation and facilities setup

- Preventive and corrective maintenance

- Process optimisation and validation

- Equipment engineering and refurbishment

- Legacy tool lifecycle extension

- Spare part manufacturing, testing, and logistics

This story is from the September 2025 edition of Bisinfotech.

Subscribe to Magzter GOLD to access thousands of curated premium stories, and 10,000+ magazines and newspapers.

Already a subscriber? Sign In

MORE STORIES FROM Bisinfotech

Bisinfotech

Toshiba Powering A Sustainable Future with its Next-Gen Technologies

We face a world of intensifying climate change, population growth, resource shortages and other issues that increasingly threaten the future of humanity.

5 mins

October 2025

Bisinfotech

IoT in Manufacturing: Transforming Production with Smart Technologies

Manufacturing has always been the backbone of industrial growth and global progress.

3 mins

October 2025

Bisinfotech

Can India's Power Infrastructure Keep Up with Its Digital Ambitions?

India’s data center industry is experiencing an unprecedented growth trajectory, driven by rapid digitalization, the rollout of 5G networks, AI adoption, and increasing cloud demand.

2 mins

October 2025

Bisinfotech

“IMC 2025: Shaping India's Digital Future"

India Mobile Congress (IMC) has evolved into Asia's largest digital technology showcase, symbolizing India's journey from a telecom-driven nation to a global digital powerhouse.

5 mins

October 2025

Bisinfotech

Shaping the Future: Ericsson India's Role in 5G Adoption and Innovation

As India races ahead with one of the fastest and most widespread 5G rollouts globally, Ericsson has been at the forefront of enabling this transformation.

5 mins

October 2025

Bisinfotech

"Driving Digital Transformation: TVS Electronics on AIDC and Automation in India"

India’s rapid digital transformation across logistics, retail, manufacturing, and healthcare is fueling unprecedented demand for enterprise-grade AIDC (Automatic Identification and Data Capture) and automation solutions.

4 mins

October 2025

Bisinfotech

Driving India's Electronics Future: Insights from Malini Narayanamoorthi, Renesas India

At Electronica India 2025, the country’s largest electronics and semiconductor event, Renesas Electronics India Pvt.Ltd. showcased its latest innovations and initiatives aimed at strengthening India’s electronics ecosystem.

3 mins

October 2025

Bisinfotech

Uttar Pradesh: Leading India's 5G & 6G Revolution

Uttar Pradesh, India's most populous state, is rapidly emerging as a frontrunner in the digital transformation landscape.

6 mins

October 2025

Bisinfotech

Top 3 Ways Infrared Thermal Sensors Improve Product Reliability in Electronics Manufacturing

As electronics manufacturing develops towards high integration and high performance, infrared thermal sensors have become a core technology that ensures product reliability, performance, and longevity.

3 mins

October 2025

Bisinfotech

Accelerating 6G and NTN Development through Network Digital Twins

Digital twins — virtual models of physical systems like 6G, NTN, and 5G — make it possible to simulate, analyse, and optimize all network systems and components, including their non-terrestrial elements.

3 mins

October 2025

Listen

Translate

Change font size