Textile Circularity - A Decade of Experiments and Experiences at Meemansa

Textile Value Chain

|October 2025

The textile industry is a paradox: it is a generator of beauty, culture, and livelihoods - yet also one of the most resource-intensive and waste-producing sectors in the world.

I. Introduction

India, with its deep textile traditions and massive industrial base, sits at the heart of this paradox.

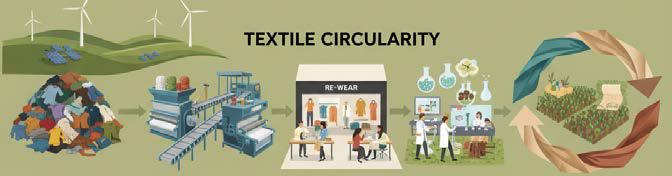

Circularity in textiles is not only about recycling garments at the end of life. It is about re-imagining the fabric value chain from its very beginning: how fibres are sourced, how fabrics are designed and cut, how garments are made and distributed, and ultimately, how they are used, reused, and disposed of.

At Meemansa, for over a decade, we have worked to embed upcycling, zero waste, and inclusivity into this value chain. Partnering with Rhino Machines, we have combined design ingenuity, engineering capabilities, and community partnerships to explore how waste can be transformed into value.

Types of Fabrics in the Waste Stream

Different fibres behave differently in their lifecycle, making the recycling of textiles particularly complex compared to other waste streams like plastics. The fabrics in today's textile waste can be broadly classified as:

This diversity shows why textile recycling is considered harder than plastic recycling. With blends dominating fast fashion, solutions must span from waste prevention (upstream design) to technological regeneration (fibre-to-fibre recycling).

Sources of Textile Waste

Waste is generated throughout the textile lifecycle:

• Upstream (Pre-production): Inefficient cutting plans, misaligned fabric widths, or design choices that create high offcut percentages.

• Midstream (Production): Side-cuts, rejected fabric rolls, trims, overstock, or misprints. This is the largest source of industrial waste.

• Downstream (Post-use): Consumer discards, returned goods, and garments at end-of-life. Blended, dyed, and mixed materials make this the hardest to recycle.

Diese Geschichte stammt aus der October 2025-Ausgabe von Textile Value Chain.

Abonnieren Sie Magzter GOLD, um auf Tausende kuratierter Premium-Geschichten und über 9.000 Zeitschriften und Zeitungen zuzugreifen.

Sie sind bereits Abonnent? Anmelden

WEITERE GESCHICHTEN VON Textile Value Chain

Textile Value Chain

EPR in Textiles: Turning Compliance into Opportunity

When the EU Comes to Panipat, It Means One Thing — The World Is Watching

3 mins

November 2025

Textile Value Chain

European Parliament Delegation Visits Panipat Recycling Cluster to Strengthen India-EU Collaboration on Circular Textiles

A high-level delegation from the European Parliament's Committee on International Trade (INTA) visited the Panipat Textile Recycling Cluster — India's largest hub for recycled textiles and circular manufacturing — during their official visit to India.

1 mins

November 2025

Textile Value Chain

Paramount Instruments: Where Innovation Turns Testing into Joy

At Paramount Instruments, innovation isn't just a Pursuit- it's in our DNA.

2 mins

November 2025

Textile Value Chain

Crafting the Future: LMW & Hami Weavelon pioneer Compact Spinning in Polyester

Manmade fibres today form the backbone of the global textile industry, driven by their versatility, performance, and ability to meet the rising demand for both everyday and specialised applications.

3 mins

November 2025

Textile Value Chain

Data is the New Thread: Weaving India's Textile Sector into a Circular Powerhouse

On November 13, 2025, at the 12th Edition of the India and Sustainability Standards (ISS) International Dialogue and Conference held at Bharat Mandapam in New Delhi, representatives from the Home Exporters Welfare Association of India (HEWA) joined industry leaders, policymakers, and international organizations to address a pressing question: How can India's textile sector meet emerging global data requirements while supporting its MSME backbone?

3 mins

November 2025

Textile Value Chain

Rieter Winding Suction Nozzle Upgrade: More Yarn, Less Energy Use

After upgrading the suction nozzles on their 32 winding machines, Sanyang Textile Co., Ltd., China, saw an increase in yarn production of 3% and a reduction of 13% in energy use. The flow-optimised, aerodynamically designed suction nozzle enables efficient upper yarn search and pickup from the package. This results in a 55% reduction in red light percentage and a significant reduction in the operator's workload.

1 mins

November 2025

Textile Value Chain

EU's Extended Producer Responsibility (EPR) Law and Its Implications for India's Textile Industry

The European Union (EU) has approved a new Extended Producer Responsibility (EPR) framework for textiles. This is a major regulatory shift that makes fashion brands and producers accountable for their products' entire lifecycle, from design and production through collection, sorting, recycling and disposal.

9 mins

November 2025

Textile Value Chain

GTE Ahmedabad 2025 Concludes Day 3 with a Huge Footfall

The 38th Garment Technology Expo (GTE) Ahmedabad 2025, co-located with the Lace & Trims Show, wrapped up its third day on an impressive note, recording around 9,700 B2B visitors. The strong industry turnout reaffirmed the expo's role as one of the most influential and business-driven platforms for garment and apparel technology in the western region.

2 mins

November 2025

Textile Value Chain

Reinterpreting Korean Street Fashion through Sustainable Design Practices

A Path through Eco-conscious Urban Fashion

7 mins

November 2025

Textile Value Chain

3D Printing in Textiles Manufacturing: A Game-Changer in Design, Sustainability, and Efficiency

The global textile and apparel industry is undergoing a radical transformation due to the convergence of digital design, advanced material technology, and next-generation manufacturing. Of the latter, few have greater potential to change how textiles are made today than additive manufacturing, better known as 3D printing.

5 mins

November 2025

Listen

Translate

Change font size