Poging GOUD - Vrij

From Brownfield to Smart Factory: Retrofitting the Past for India's Manufacturing Future

Bisinfotech

|September 2025

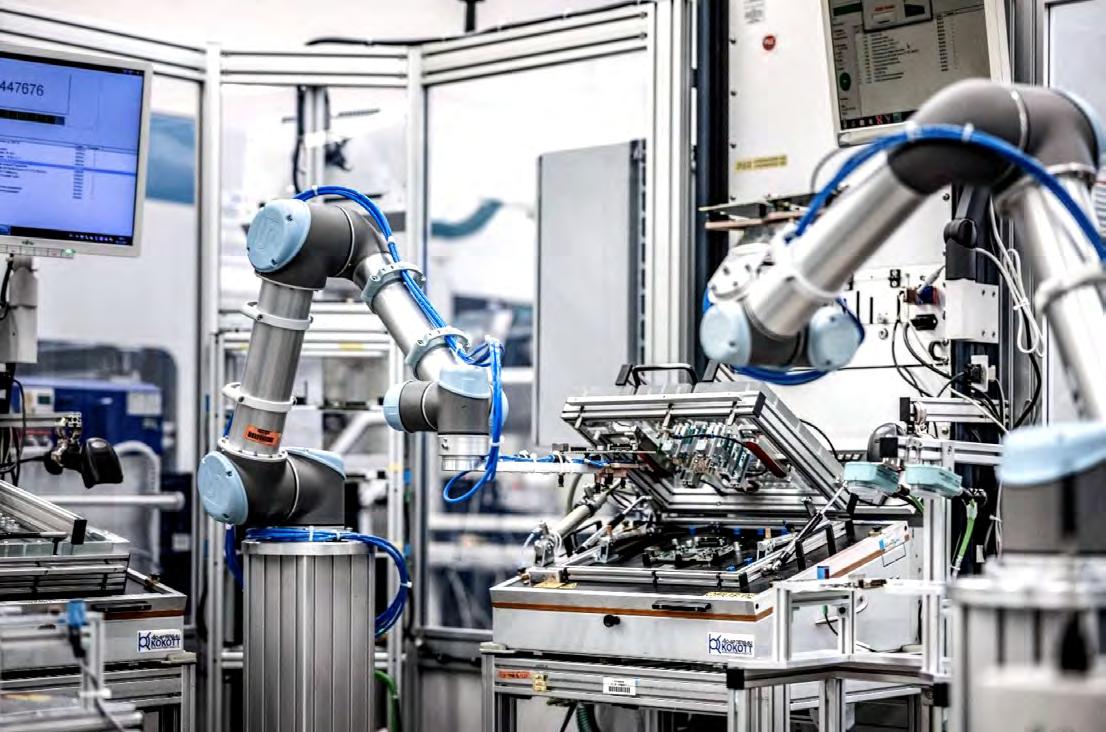

India's manufacturing industry is at a turning point. Rising operational costs, energy inefficiencies, increasing customer demands, and a persistent shortage of skilled labour are forcing manufacturers to reimagine the way they work. Digitalisation and automation are fast emerging as the critical enablers to meet these challenges head-on.

-

Contrary to popular belief, modernisation doesn't mean tearing down and replacing every machine with brand-new equipment. India’s industrial base is built on thousands of legacy plants, operating a mix of machinery of varying ages and capabilities. Many of these plants have already begun incorporating modern automation processes without discarding their older assets. The Smart Factory journey begins with identifying measurable business goals for the organization as first step.

A strong roadmap allows manufacturers to integrate automation features into production lines while ensuring harmony between old and new systems. One of the most powerful tools to make this possible is the comprehensive Digital Twin—a virtual representation of a product and its production system that enables simulation, testing, and optimisation without disrupting ongoing operations.

Starting small, starting flexibly

For Indian manufacturers, the idea of going digital can seem daunting, especially when budgets are tight and downtime is costly. Yet, becoming a digital enterprise brings measurable benefits—higher productivity, lower costs, improved operational efficiency, and opportunities to upskill the workforce. The Digital Twin enables companies to simulate their production environment virtually and identify where automation can be introduced with minimal disruption. In India’s highly cost-sensitive market, this “start small” approach allows manufacturers to build capability step-by-step rather than investing heavily upfront.

A practical entry point is the Production Digital Twin. By testing modern automation techniques virtually before physical implementation- manufacturers can avoid expensive mistakes, shorten deployment timelines, and ensure that investments align with long-term goals.

Dit verhaal komt uit de September 2025-editie van Bisinfotech.

Abonneer u op Magzter GOLD voor toegang tot duizenden zorgvuldig samengestelde premiumverhalen en meer dan 9000 tijdschriften en kranten.

Bent u al abonnee? Aanmelden

MEER VERHALEN VAN Bisinfotech

Bisinfotech

Toshiba Powering A Sustainable Future with its Next-Gen Technologies

We face a world of intensifying climate change, population growth, resource shortages and other issues that increasingly threaten the future of humanity.

5 mins

October 2025

Bisinfotech

IoT in Manufacturing: Transforming Production with Smart Technologies

Manufacturing has always been the backbone of industrial growth and global progress.

3 mins

October 2025

Bisinfotech

Can India's Power Infrastructure Keep Up with Its Digital Ambitions?

India’s data center industry is experiencing an unprecedented growth trajectory, driven by rapid digitalization, the rollout of 5G networks, AI adoption, and increasing cloud demand.

2 mins

October 2025

Bisinfotech

“IMC 2025: Shaping India's Digital Future"

India Mobile Congress (IMC) has evolved into Asia's largest digital technology showcase, symbolizing India's journey from a telecom-driven nation to a global digital powerhouse.

5 mins

October 2025

Bisinfotech

Shaping the Future: Ericsson India's Role in 5G Adoption and Innovation

As India races ahead with one of the fastest and most widespread 5G rollouts globally, Ericsson has been at the forefront of enabling this transformation.

5 mins

October 2025

Bisinfotech

"Driving Digital Transformation: TVS Electronics on AIDC and Automation in India"

India’s rapid digital transformation across logistics, retail, manufacturing, and healthcare is fueling unprecedented demand for enterprise-grade AIDC (Automatic Identification and Data Capture) and automation solutions.

4 mins

October 2025

Bisinfotech

Driving India's Electronics Future: Insights from Malini Narayanamoorthi, Renesas India

At Electronica India 2025, the country’s largest electronics and semiconductor event, Renesas Electronics India Pvt.Ltd. showcased its latest innovations and initiatives aimed at strengthening India’s electronics ecosystem.

3 mins

October 2025

Bisinfotech

Uttar Pradesh: Leading India's 5G & 6G Revolution

Uttar Pradesh, India's most populous state, is rapidly emerging as a frontrunner in the digital transformation landscape.

6 mins

October 2025

Bisinfotech

Top 3 Ways Infrared Thermal Sensors Improve Product Reliability in Electronics Manufacturing

As electronics manufacturing develops towards high integration and high performance, infrared thermal sensors have become a core technology that ensures product reliability, performance, and longevity.

3 mins

October 2025

Bisinfotech

Accelerating 6G and NTN Development through Network Digital Twins

Digital twins — virtual models of physical systems like 6G, NTN, and 5G — make it possible to simulate, analyse, and optimize all network systems and components, including their non-terrestrial elements.

3 mins

October 2025

Listen

Translate

Change font size