A Combined Scroll Saw And File Attachment For Your Lathe

Model Engineers' Workshop

|December 2019

Mogens Kilde gives a step by step guide to aid beginners and the more experienced in making this useful attachment. - Part 3.

-

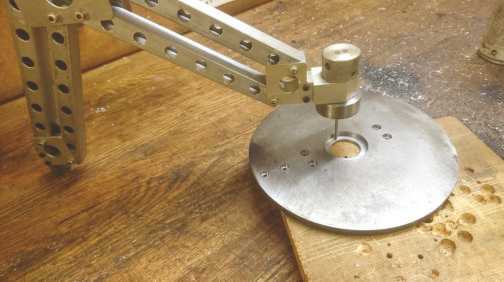

To finish the plates, they were drilled, again on the bench mill, photo 62Next part I made was the plate that fixes the saw cutting blade, this I call “scroll saw arm”, fig. 12.

This part was made from 3.0mm mild steel sheet and the first job was to mark out the outer shape according to the figure, photo 64.

Next, the part was roughly cut out using my band saw, photo 65. Finally, the edge was filed smooth, photo 66 to finish the arm.

The 4.5mm holes where drilled in the bench drill, photo 67 and the oblong 4.5 x 8.5 slot was made using a round file.

Next part I made was the bracket that should hold the saw cutting blade at the upper end, fig 13.

This part was made from a piece of 14 x 14mm hot rolled steel, and after cutting a blank a little over size according to the figure, all sides was milled to final dimension as per the figure, photo 68.

Next the M4 holes were drilled and tapped, photo 69.

As the idea with this tool is that it can be used as a scroll saw and a filing machine, I’ve designed it with interchangeable support for the work pieces that are to be worked on. Therefore, the next part I made was a support button for the scroll saw application, fig 14.

In fact, I made a set of buttons so these later could be adapted to appropriate jobs.

Dit verhaal komt uit de December 2019-editie van Model Engineers' Workshop.

Abonneer u op Magzter GOLD voor toegang tot duizenden zorgvuldig samengestelde premiumverhalen en meer dan 9000 tijdschriften en kranten.

Bent u al abonnee? Aanmelden

MEER VERHALEN VAN Model Engineers' Workshop

Model Engineers' Workshop

Readers' Workshops - Patrick Cubbon

Patrick Cubbon describes his workshops – a portable one from 1963 and the current accommodation

2 mins

May 2020

Model Engineers' Workshop

Desktop Gear Hobbing

Toby Kinsey has designed this fascinating piece of gearmaking equipment

9 mins

May 2020

Model Engineers' Workshop

The John Stevenson Trophy 2020

Many readers and forum members will remember John Stevenson, a contributor to MEW but best known for his larger-than life presence on the Model Engineer forum.

3 mins

May 2020

Model Engineers' Workshop

From the Archives: Twist drill Sharpening by the Four Facet Method

Giles Parkes, MEW Issue 64, February/March 2000

4 mins

May 2020

Model Engineers' Workshop

Dividing on the Warco 220 Lathe

Peter Shaw describes a mandrel dividing attachment for this popular lathe that can be adapted to fit many other benchtop machines

8 mins

May 2020

Model Engineers' Workshop

Choosing Steels

Stub Mandrel offers some advice on choosing the right steel for the job

7 mins

May 2020

Model Engineers' Workshop

A Storage Story

Robin King shares the lessons learned from his experience of workshop moves

8 mins

May 2020

Model Engineers' Workshop

A Simple Drill Grinding Aid

A newcomer to our hobby was having trouble sharpening drills, so Howard Lewis made a simple aid for him

2 mins

May 2020

Model Engineers' Workshop

Yet Another Bodge-Up!

Peter Shaw finds a use for some aged homebrew slot drills.

5 mins

March 2020

Model Engineers' Workshop

Workshop Press Tooling Part 2

Will Doggett makes a set of tooling for his press tool described starting in issue 285

5 mins

March 2020

Translate

Change font size