A HISTORY OF OIL ANALYSIS

MACHINERY LUBRICATION INDIA

|September - October 2023

In this issue we will look at the inception and rise of oil analysis. Specifically, we will be looking at the development and implementation of elemental spectroscopy, ferrography and infrared spectroscopy.

-

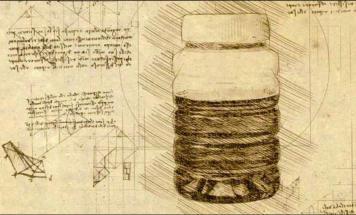

Lubricants have been inspected and monitored for perhaps as long as they've been in use. But until the second half of the 20th century, inspection and monitoring was limited to temperature, pressure and the occasional check for oil color and viscosity. There are also references to blotter spot testing of in-service lubricants in the late 19th century.

Prior to the widespread use of routine oil analysis for condition monitoring, there were numerous methods to examine the physical, chemical and performance properties of new lubricants. These properties included viscosity, flash point, pour point, density, total in solubles and water contamination. These early tests were promoted by oil companies as a way to characterize the basic properties of different lubricants and to ensure the quality of their product. These tests also served the purpose of legally defending the lubricant manufacturer in the event of machine failure.

Between 1946 and 1948, the Denver and RIO Grande Railroad began using elemental spectroscopy to test lubricants for the abnormal presence of wear metals, namely aluminum, copper, iron and lead. This practice was implemented with the interest of avoiding accidents and reducing mechanical failure. The focus on wear metals can be credited for a paradigm shift regarding lubricant testing, shifting the focus (although not entirely) from testing lubricant health and-performance to monitoring machine health. This effort aimed at reliability was successful, and other railroad companies soon implemented similar practices.

EARLY USE OF ELEMENTAL SPECTROSCOPY

Denne historien er fra September - October 2023-utgaven av MACHINERY LUBRICATION INDIA.

Abonner på Magzter GOLD for å få tilgang til tusenvis av kuraterte premiumhistorier og over 9000 magasiner og aviser.

Allerede abonnent? Logg på

FLERE HISTORIER FRA MACHINERY LUBRICATION INDIA

MACHINERY LUBRICATION INDIA

PREDICT OIL USEFUL LIFE WITH REAL-TIME DATA

Oil is the life of any hydraulic or lubrication system.

8 mins

November – December, 2025

MACHINERY LUBRICATION INDIA

HOW THE RIGHT LUBRICATION TOOLS AND HARDWARE INFLUENCE MACHINE RELIABILITY

Having spent a good portion of my career around heavy machinery, both in the military and later in the civilian world, I’ve come to realize one critical fact: the tools you use matter just as much as the skills you have.

4 mins

November – December, 2025

MACHINERY LUBRICATION INDIA

Unlocking the Power of Oil Analysis & Particle Counting

Lubrication practices ensure peak performance and longev ity in machinery maintenance.

4 mins

November – December, 2025

MACHINERY LUBRICATION INDIA

BEYOND THE LABEL: UNDERSTANDING LUBRICANT TECHNICAL AND SAFETY DATA SHEETS

Over the years in lubrication, I have noticed that many professionals either overlook or misinterpret lubricant datasheets, especially Product Datasheets (PDS), which are key to selecting the proper lubricant. While Safety Datasheets (SDS) are widely known due to compliance requirements, the PDS holds the technical insights needed for informed decision-making. Yet, it is often misunderstood or ignored.

3 mins

November – December, 2025

MACHINERY LUBRICATION INDIA

SMART FILTRATION IN HEAVY INDUSTRIES:

PROTECTING WORKERS IN CEMENT AND STEEL MANUFACTURING

5 mins

November – December, 2025

MACHINERY LUBRICATION INDIA

IOCL & INFINEUM FORGE STRATEGIC LUBRICANT PARTNERSHIP

Infineum India and Indian Oil Corporation Limited (IOCL) have signed a strategic Memorandum of Understanding (MoU) aimed at deepening their collaboration to unlock long-term business value and drive innovation in India's mobility sector. The agreement was formalized at IOCL's Mumbai office, with Bakim Patra, Executive Director (Lubes) at IOCL, and Harshad Jambaulikar, General Manager of Infineum India, as the principal signatories.

1 min

November – December, 2025

MACHINERY LUBRICATION INDIA

CONTAMINATION REALIZATION: A CASE EXAMPLE AT A STEEL MILL

Condition monitoring, contamination control, lubrication excellence, and machine reliability are keywords that are often overused and misunderstood.

6 mins

November – December, 2025

MACHINERY LUBRICATION INDIA

BREAKING DOWN THE BASICS: A LESSON IN ASSET RELIABILITY

Before you go marching down to your reliability engineers and ask questions like, “What are the top 10 worst performing assets in our production line?”, it’s important to know the actual difference between an asset and reliability.

7 mins

November – December, 2025

MACHINERY LUBRICATION INDIA

EFFECTIVE USE OF THE PATCH TEST FOR SIMPLE ON-SITE ANALYSIS

The very best oil analysis programs incorporate some degree of onsite analysis. For most plants, mills, and mines, particle monitoring is the most productive onsite oil analysis activity available.

4 mins

November – December, 2025

MACHINERY LUBRICATION INDIA

CAFFEINE VS. CALM: FINDING THE RIGHT ENERGY BALANCE DURING WORK HOURS

For many of us, the workday doesn't officially begin until the first sip of coffee. In industrial and corporate settings alike, caffeine is often seen as a silent coworker, fueling early mornings, long shifts, and back-to-back meetings.

2 mins

November – December, 2025

Translate

Change font size