Prøve GULL - Gratis

THE DIE IS CAST

Manufacturing Today

|March 2020

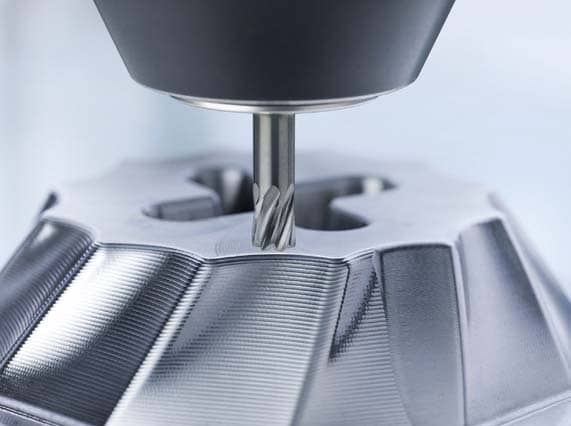

DIE AND MOULD MAKING IS REACHING NEW LEVELS IN INDIA WITH MODERN TECHNOLOGIES COMING IN

-

IT IS SAID TO BE THE BEGINNING OF manufacturing. The final product that a company ships out begins with a die and mould. Across industries that manufacture ‘solid’ products, it must have a die and mould. These vary based on the product, the component or sometimes even a minute part. The type of material that is used for making the mould depends upon the product that is going to be made with the mould.

More often than not, the die and mould making industry supply tools to companies from cross vertical domains such as automotive, aerospace, industrial machinery and heavy engineering, defence to consumer goods and electronics. In all the above, it is the automotive industry that is the largest source for die and moulds. Newer industries like aerospace and medical equipment are growing, but that is niche and little is spoken about that.

Ramakant Reddy, MD, LMT Tools India, says, “The major change in vehicle systems will be in the way it runs in the future. The diesel and petrol engines will be replaced in part by electric vehicles. This will reduce the need for hot forging dies for components like crankshaft, connecting rods, etc. To reduce body weight there would be more use of plastics & composites which again will have an effect on punching & pressing dies. With increased use of aluminium, plastics, and composites there will be more opportunities for injection moulding, die casting dies, etc. The die and mould manufacturers should adapt themselves to this change of requirement so that the bottom line is not affected.”

Denne historien er fra March 2020-utgaven av Manufacturing Today.

Abonner på Magzter GOLD for å få tilgang til tusenvis av kuraterte premiumhistorier og over 9000 magasiner og aviser.

Allerede abonnent? Logg på

FLERE HISTORIER FRA Manufacturing Today

Manufacturing Today

THE OPEN AUTOMATION MOVEMENT

How Schneider Electric is powering India's industrial future with Open, Software-Defined Automation

10 mins

December 2025

Manufacturing Today

A look back and the road ahead

The year 2025 will be remembered as a period of recalibration for India's manufacturing sector. Far from a mere continuation of post-pandemic recovery, it was a year defined by the complex interplay of global economic headwinds, rapid technological adoption and a decisive domestic push towards self-reliance and sustainability. For an industry that forms the bedrock of the nation's economic ambition, 2025 was less about incremental growth and more about structural transformation, setting the stage for a more competitive and demanding 2026.

23 mins

December 2025

Manufacturing Today

The fifth dimension

How 5-Axis machining is redefining precision and agility in manufacturing.

6 mins

December 2025

Manufacturing Today

Axirium Aerospace raises $3.5M to boost precision manufacturing

The investment will expand Axirium's first manufacturing facility.

1 min

December 2025

Manufacturing Today

Flying Wedge, AP govt to build India's first combat UAV hub

The project by Flying Wedge positions Andhra Pradesh as a strategic hub for next-generation defence and aerospace manufacturing.

1 min

December 2025

Manufacturing Today

Monolithisch India acquires Mineral India

Mineral India reported a turnover of Rs 49.39 crore and a PAT of Rs 6.30 crore, with a robust customer base in Chhattisgarh and central India.

1 min

December 2025

Manufacturing Today

Smart. Mobile. Made.

India's mobile and accessories industry is rapidly transforming into a high-tech, sustainable, and self-reliant manufacturing ecosystem driven by innovation, automation, and local value creation.

5 mins

December 2025

Manufacturing Today

Karnataka to build 200-acre semiconductor park in new KWIN City

Karnataka announces a 200-acre semiconductor park within the upcoming KWIN City, aiming to strengthen India's advanced manufacturing and deep-tech ecosystem

1 mins

December 2025

Manufacturing Today

Driving Efficiency & Sustainability Through Advanced Power Transmission Systems

In today's industrial landscape, efficiency and sustainability are no longer optional; they're essential. PowerBuild, with its decades of engineering excellence, is at the forefront of this transformation. Through its advanced range of power transmission products, the company is actively helping industries minimize energy consumption, extend machine lifespans, and transition toward greener manufacturing practices. PowerBuild's entire gearbox and geared motor portfolio is engineered with energy optimization at its core. Whether it's the Series M Helical Inline Geared Motors, known for their compact design and high efficiency, or the Series K Helical Bevel Geared Motors, offering torque up to 50,000 Nm with minimal energy loss, each product is built to maximize output while reducing unnecessary power draw. These solutions are precision-designed to minimize friction, vibration, and wear three major contributors to energy inefficiency and mechanical failure.

1 mins

December 2025

Manufacturing Today

Is your facility ready for 24/7 automation?

Lights-out manufacturing is rapidly emerging as the future of Indian industry, but its success hinges on blending advanced automation with strong digital infrastructure, cybersecurity, and human adaptability.

6 mins

December 2025

Translate

Change font size