Faster time to market with Continuous Direct Compression

Express Pharma

|July 2025

Development and production using Continuous Manufacturing

-

The production of medicines and food supplements is experiencing a real innovation boost thanks to Continuous Manufacturing processes. For a long time, manufacturers hesitated in the face of cost-intensive conversions, time-consuming revalidation and complex systems with large space requirements. However, Continuous Manufacturing is now proving that endto-end production can also be space-saving, uncomplicated and economical. With the FE CPS, Fette Compacting is underlining this development and at the same time positioning itself as an integrated process partner.

In order to make continuous manufacturing more economically attractive, Fette Compacting fundamentally reviewed the concept of continuous direct compression a few years ago. The original approach was still strongly oriented towards established principles of pharmaceutical processing and the combination of existing systems. In order to fully utilize the advantages of continuous direct compression, it was necessary to rethink the entire process and system design.

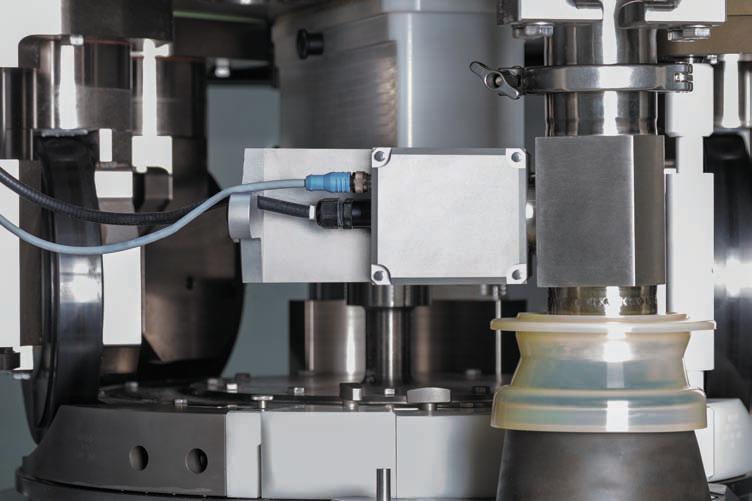

The resulting processing system FE CPS (Continuous Processing System) establishes a reliable, powerful and highly flexible technology for the continuous production of pharmaceutical and nutraceutical products. The principle of Direct Compression enables the immediate transfer of the powder: it is transferred from the dosing-mixing unit directly to the tablet press via a flexible transport system (Fig. 1). Unlike conventional processes with wet or dry granulation, this eliminates several process steps, significantly reducing space requirements, energy consumption and overall costs. The developers designed the system for a wide range of application scenarios: It processes a wide range of ingredients with a flexible throughput of between five and over 200 kilograms per hour.

Inline quality control

Inline quality control このストーリーは、Express Pharma の July 2025 版からのものです。

Magzter GOLD を購読すると、厳選された何千ものプレミアム記事や、10,000 以上の雑誌や新聞にアクセスできます。

すでに購読者ですか? サインイン

Express Pharma からのその他のストーリー

Express Pharma

The invisible threat: Why packaging inks are the next major recall risk for pharma

Jatin Takkar, Head - Product Safety & Regulatory, Siegwerk India writes that packaging is emerging as a potential source of contamination due to unsafe ink chemistries. With global standards evolving, the industry must shift from reactive compliance to a proactive 'Safe by Design' approach that ensures packaging inks are as safe as the medicines they guard

4 mins

December 2025

Express Pharma

Beyond the machine: How intelligent packaging design elevates parenteral delivery

For sensitive parenteral products, the packaging is as critical as the drug itself. Uhlmann demonstrates how deep design competence turns packaging challenges into patient-centric solutions

2 mins

December 2025

Express Pharma

Ensuring Clean Room Integrity with Prime Clean Reset High-Speed Doors: Minimizing Air Permeability and Leakages

High-speed doors for clean rooms are specialized industrial doors essential for maintaining controlled environments.

3 mins

December 2025

Express Pharma

JULABO introduces Green Edition Refrigerated Circulators using natural refrigerants for sustainable lab cooling

JULABO launches its Green Edition range of refrigerated circulators designed to support laboratories in reducing carbon emissions, improving energy efficiency, and aligning with global environmental regulations

2 mins

December 2025

Express Pharma

Flexotherm Heating Tapes & Cords

Tempo's Flexotherm heating tapes and cords provide a safe, flexible, and efficient solution for maintaining solvent temperature across a wide range of industrial processes

1 mins

December 2025

Express Pharma

PRUV® -The original Sodium Stearyl Fumarate

JRS Pharma's PRUV® is the original sodium stearyl fumarate (SSF) introduced in the market over 20 years ago

5 mins

December 2025

Express Pharma

We continue to invest heavily in quality, regulatory compliance, and modernisation

Rishad Dadachanji, MD, Kaisha Packaging shares insights on emerging industry trends, new technologies showcased at CPhI & P-MEC, and how the Dadachanji Group is strengthening its integrated ecosystem to serve both domestic and global pharma markets

3 mins

December 2025

Express Pharma

Romaco begins local format part production in India

The Noack N 950E blister packaging machine with Indian-produced format parts to debut at CPHI & PMEC India 2025, followed by installation at the Romaco India Experience Centre in Hyderabad

4 mins

December 2025

Express Pharma

We built our business by obsessing over excipients

Shivang Zaveri, Director, Transchem Corporation Pharma; discusses Transchem's approach to excipients, innovation, and market strategy with Express Pharma.

2 mins

December 2025

Express Pharma

India is a cornerstone of Fette Compacting's global strategy

Ashok Gourish, Managing Director, Fette Compacting India, discusses India's pivotal role in the company's global growth, backed by expanded services, digital transformation support, and a strengthened Competence Center in Goa, in conversation with Express Pharma

5 mins

December 2025

Listen

Translate

Change font size