試す 金 - 無料

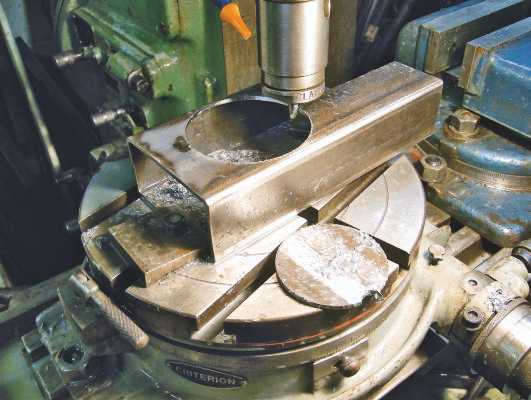

An Inverted ‘Ross Yoke' Watercooled Stirling Engine

Model Engineer

|4635

As with all my hot air engines they are cheap to build, mostly from scrap

-

This engine was built during the horrendous snows of the 2018 winter months in my garden workshop (photo 1). As with all my hot air engines they are cheap to build, mostly from scrap. This is my 5th attempt and can be seen running on YouTube along with my other large Stirling engines, running in the workshop or at shows. The only bought in casting is the 9 inch flywheel casting from eBay. It was theoretically cheap, except for the heating costs of keeping a large workshop and me alive - but only just!

I wanted a slow, low compression, educational engine that was different with lots to see. I stumbled across a working animated ‘Ross Yoke’ crank design on YouTube and this fascinated me. I couldn’t leave it alone. That meant it would also fascinate others - it ticked all the boxes – so I zoomed it to the scale I wanted and printed out several copies. This led to some research into the finer points - as always, these things are far more complex than they first appear. The mathematics are horrendous, frightening and eventually were to come back and bite me for getting it wrong.

Eventually, after many sketches, I came up with this layout. It has many good points – it’s inherently strong and stable, has built in water cooling tanks (always a major problem, a serious must have), no water jacket casting needed, compact, interesting and quite lightweight, by my standards, very visible and hypnotic the seeds were sown for yet another unusual engine that I promised not to make.

このストーリーは、Model Engineer の 4635 版からのものです。

Magzter GOLD を購読すると、厳選された何千ものプレミアム記事や、10,000 以上の雑誌や新聞にアクセスできます。

すでに購読者ですか? サインイン

Model Engineer からのその他のストーリー

Model Engineer

WORKSHOP TIP - Boring Eccentrics

I am making a 1 inch Minnie traction engine and have arrived at the machining of the eccentric straps.

3 mins

4635

Model Engineer

Wenford A 7¼ Inch Gauge 2-4-0 Beattie Well Tank

The stage has now been reached where the well tank body can be completed but beforehand there are some internal details to add.

4 mins

4635

Model Engineer

Vertical Boiler Locomotives

Vertical Boiler Locomotives

4 mins

4635

Model Engineer

Union Nuts, and How to Make Them

These are quite different from those commercially available and are made from copper

3 mins

4635

Model Engineer

SHOWCASE Paul's Engine

One day my son Paul came to me and asked if we could make something in my workshop, so that he could learn engineering processes.

1 min

4635

Model Engineer

CLUB NEWS

My secret’s out!

9 mins

4635

Model Engineer

Building Dancer - The Boiler

Dancer needed a boiler that would be somewhat larger than the size permitted under the Model Engineering exemptions in the New Zealand regulations.

10 mins

4635

Model Engineer

An Inverted ‘Ross Yoke' Watercooled Stirling Engine

As with all my hot air engines they are cheap to build, mostly from scrap

5 mins

4635

Model Engineer

A Draught Proposal

A Draught Proposal

12 mins

4635

Model Engineer

A Boiler Feed Pump

A Boiler Feed Pump

2 mins

4635

Translate

Change font size