Essayer OR - Gratuit

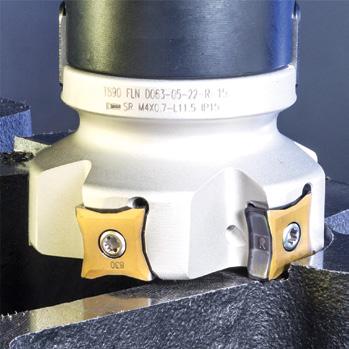

ISCAR'S FACE & SHOULDERS MILLS

The Machinist

|April 2023

The world of metalworking is undergoing major changes. Complex machining processes are unimaginable without the utilization of face milling operations. Face milling processes facilitate the preparation of datum surfaces by producing planes and flats and enable improving precision and surface quality parameters. Moreover, the production of many rotating parts is incomplete without face milling. Face milling is the very operation that cannot be undermined.

-

In face milling, the axis of a cutter is normal to the machined surface. A large majority of face mills or surface milling cutters are common indexable tools in shell mill configuration. They feature various tool cutting edge angles (entering angles) such as 45°, 60°, 65°, 75°, 90°. Face mills intended specifically for productive rough machining by use of high feed milling (HFM) methods have a significantly smaller cutting-edge angle, typically 10°-17°. In some cases, shell mills that mount round inserts enable extremely strong cutting edges. The cutting-edge angle has an impact on the decomposition of the cutting force, which acts on the plane of the cutter axis, on radial and axial components referred to as radial, and axial cutting forces. With all else being equal, this angle defines the maximum depth of cut. The cutting-edge angle largely determines the application field of a face mill making 45° face mills most versatile. Such mills have an important advantage that stipulates a firstchoice selection of 45° cutters in face milling, specifically when machining open plane surfaces. These cutters assure a good balance of radial and axial cutting forces, a high-quality machined surface, and favorable cutting conditions when a tool enters or exits the material being machined. The most common face mill types are 45° cutters.

Cette histoire est tirée de l'édition April 2023 de The Machinist.

Abonnez-vous à Magzter GOLD pour accéder à des milliers d'histoires premium sélectionnées et à plus de 9 000 magazines et journaux.

Déjà abonné ? Se connecter

PLUS D'HISTOIRES DE The Machinist

The Machinist

CUTTING THROUGH THE TOUGH

As aerospace manufacturing increasingly relies on high-performance alloys and composites, innovative cutting tool technologies are helping industry overcome the challenges of machining difficult-to-cut materials.

4 mins

November 2025

The Machinist

INDIA'S MANUFACTURING SECTOR BACK IN MOTION

Rising production, renewed investment, and cautious optimism define India's manufacturing landscape as industries rebound from uncertainty and brace for steady growth.

4 mins

November 2025

The Machinist

INDIA'S MINING & CONSTRUCTION EQUIPMENT SECTOR AIMS FOR $45 BILLION BY 2030

As India builds at an unprecedented pace, its mining and construction equipment sector is set to become a global powerhouse by 2030.

4 mins

November 2025

The Machinist

KENNAMETAL UNVEILS ADVANCED MINING TOOLING SOLUTIONS AT IME 2025

At IME 2025 in Kolkata, Kennametal will showcase its latest high-performance tooling and wear-resistant technologies engineered to boost mining productivity, safety, and equipment life.

2 mins

November 2025

The Machinist

CYBER THREATS LEAD MANUFACTURING CONCERNS

A new global survey shows cyber-attacks, environmental pressures, and social issues are now the biggest threats to manufacturing reputation.

3 mins

November 2025

The Machinist

MTX CONNECT JAMSHEDPUR 2025

IMTMA and CII to host the third edition of MTX Connect from November 3-4 at the Cruze Premium Boutique Hotel, Jamshedpur

1 mins

November 2025

The Machinist

INNOVATION TAKES CENTER STAGE AT TECHNOLOGY EVENING IN PUNE

GROB, Kennametal, Renishaw and OPEN MIND Come Together for a Power-Packed Technology Evening in Pune, Showcasing Innovation and Collaboration in Advanced Manufacturing

1 mins

November 2025

The Machinist

IGUS EXPANDS READYCABLE PORTFOLIO WITH NEW CABLES FOR INDUSTRIAL CAMERA TECHNOLOGY

Ready-to-connect, durable and tested cables with Keyence plug-in connectors increase the reliability of vision systems

2 mins

November 2025

The Machinist

EMPOWERING SMART MANUFACTURING

OMRON Automation Center Bengaluru is empowering Indian manufacturers with real-world automation solutions and IT-OT integration to drive MSME growth.

3 mins

November 2025

The Machinist

AUMOVIO TRANSFORMS BENGALURU METRO STRETCH INTO A GREEN CORRIDOR OF ART

AUMOVIO India and Vibhinna India Foundation turn 230 medians and 195 metro pillars into a lush, art-filled urban landmark that blends ecology with culture.

2 mins

November 2025

Translate

Change font size