Versuchen GOLD - Frei

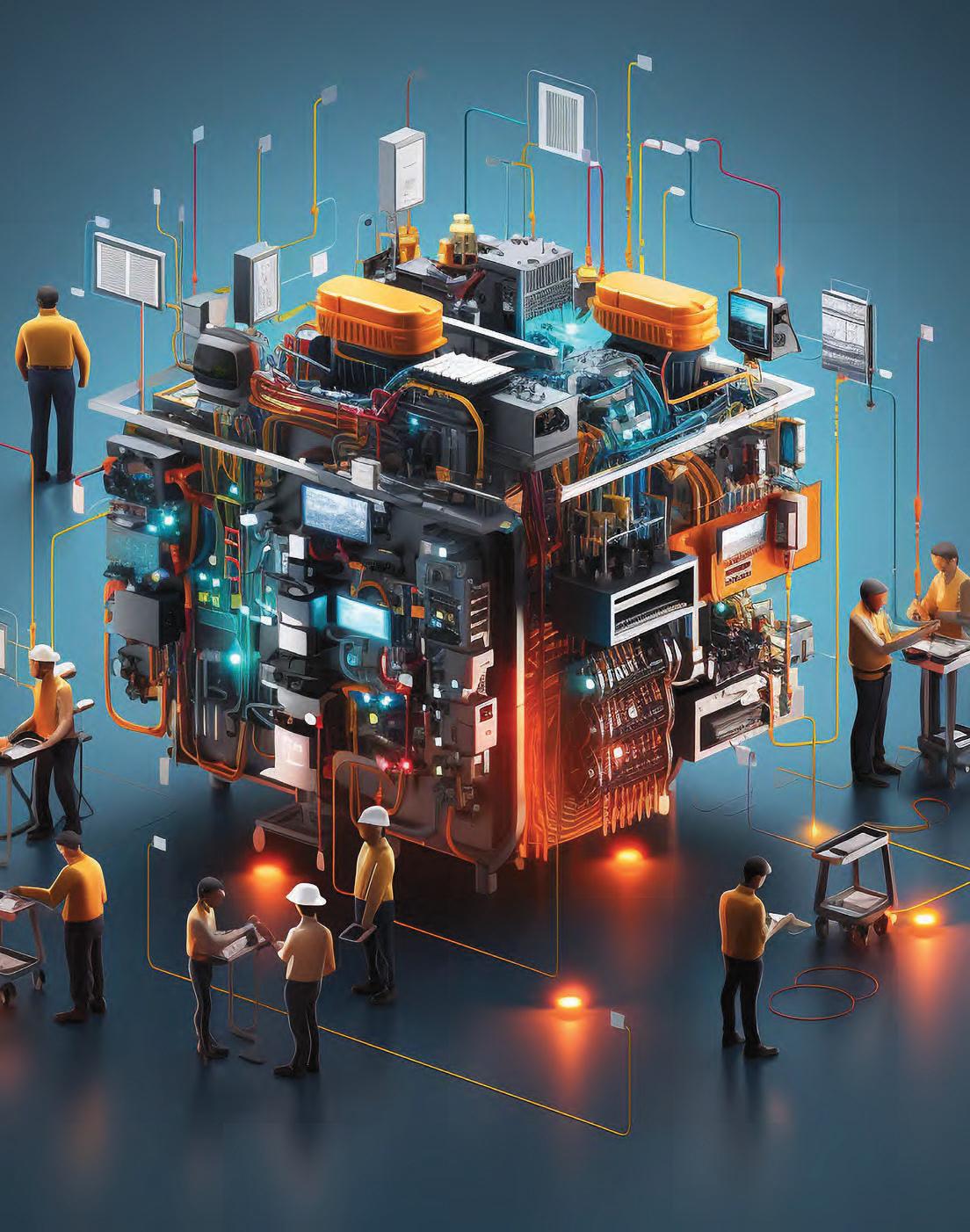

How AI and ML Are Revolutionizing Industrial IoT for Predictive Maintenance and Operational Efficiency

Bisinfotech

|August 2025

In industries that run on efficiency and timelines, downtime is a silent cost that eats into profit and productivity.

-

For decades, sectors like manufacturing, energy, heavy engineering and logistics have tried to tame this disruption with regular maintenance routines and periodic checks. Yet machines fail, parts wear out and breakdowns happen when they are least expected. The traditional playbook is no longer enough. That is why a fundamental shift is underway, one where Artificial Intelligence (AI) and Machine Learning (ML) are not just 'buzzwords' but are actively shaping how industrial systems think and respond.

We are living in an era where machines generate more data than humans can manually track and interpret. This data is not noise. It holds patterns, insights and early warnings that conventional maintenance systems often miss. Industrial internet of things (IoT) brings these machines online and AI gives them the ability to learn from every movement, every vibration, every degree of heat they emit. Together, they are not only helping industries move from reactive to predictive models but are also transforming how we look at operational efficiency itself. This is not just about saving time or reducing cost. It is about reimagining the very structure of industrial intelligence and resilience.

Predictive Maintenance Is Not a Feature. It Is a Mindset Shift.

Most industrial plants today operate under some version of scheduled or preventive maintenance. At face value, this seems proactive. But in reality, it often leads to over-servicing of machines that don't need it or worse, missed signs in machines that do. The result is lost hours, unexpected shutdowns and increased operational costs.

Diese Geschichte stammt aus der August 2025-Ausgabe von Bisinfotech.

Abonnieren Sie Magzter GOLD, um auf Tausende kuratierter Premium-Geschichten und über 9.000 Zeitschriften und Zeitungen zuzugreifen.

Sie sind bereits Abonnent? Anmelden

WEITERE GESCHICHTEN VON Bisinfotech

Bisinfotech

Novocomms Secures Grant to Develop Advanced Switchable Antennas

Novocomms has secured a government-backed grant to develop advanced switchable antenna technologies aimed at improving connectivity across multiple frequency bands.

1 min

January 2026

Bisinfotech

Anritsu Advances Satellite-Based 5G with First-Ever PTCRB NTN Certification

Anritsu has achieved the world's first PTCRB certification for select RF Conformance Test (RFCT) cases for 5G NR Non-Terrestrial Networks (NTN), in collaboration with Samsung.

1 min

January 2026

Bisinfotech

Mouser Expands IoT Offerings with Telit Cinterion

ROHM Semiconductor and Tata Electronics have formed a strategic partnership to strengthen their presence in the semiconductor business, focusing on advanced semiconductor solutions for automotive, industrial, and consumer electronics applications.

1 min

January 2026

Bisinfotech

Russian Delegation Explores Technology Collaboration with Karnataka Minister

L&T Technology Services (LTTS) has strengthened its semiconductor and electronics design services portfolio, targeting automotive, industrial, and telecom customers.

1 min

January 2026

Bisinfotech

Foxconn Explores Deeper Electronics Manufacturing Expansion in India

Foxconn is exploring further expansion of its electronics manufacturing operations in India, extending beyond smartphones into automotive electronics, industrial systems, and component manufacturing.

1 min

January 2026

Bisinfotech

Kaynes Technology Strengthens Semiconductor Manufacturing Partnerships

Kaynes Technology has deepened its engagement in the semiconductor and electronics manufacturing space through new partnerships and capacity expansion plans.

1 min

January 2026

Bisinfotech

Mouser Expands IoT Offerings with Telit Cinterion

Mouser Electronics has signed a global distribution agreement with Telit Cinterion to expand its enterprise IoT offerings.

1 min

January 2026

Bisinfotech

Analog Devices Launches Wideband RF Agile Transceiver Solution

Analog Devices has launched a new wideband RF agile transceiver solution designed to support next-generation wireless, aerospace, and defense applications.

1 min

January 2026

Bisinfotech

Anthony Enzor-DeMeo Appointed CEO of Mozilla

Mozilla has named Anthony Enzor-DeMeo as its new Chief Executive Officer, signaling a renewed focus on privacy-first software and open-source innovation.

1 min

January 2026

Bisinfotech

Aaronia Unveils Next-Gen RF Intelligence and Counter-Drone Solutions at AOC 2025

Aaronia AG is set to unveil its latest signal analysis and drone detection solutions at AOC 2025, showcasing advanced technologies designed for modern electronic warfare and spectrum monitoring challenges.

1 min

January 2026

Listen

Translate

Change font size