Versuchen GOLD - Frei

GRINDING FLANGES AND JOURNALS SIMPLY AND PRECISELY

Manufacturing Today

|October 2020

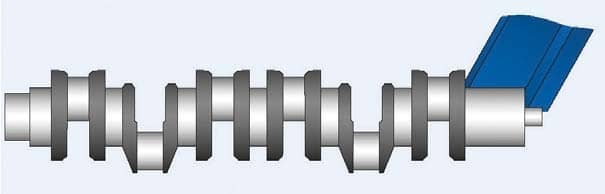

THE THYSSENKRUPP CRANKSHAFT COMPANY IN DANVILLE, IL, USES THE NUMERIKA GH1500 MACHINE FROM ZEMA TO GRIND THEIR CRANKSHAFTS. THE RELIABLE EXTERNAL GRINDING MACHINE WORKS IN A THREE-SHIFT OPERATION SEVEN DAYS A WEEK, GRINDING LF ANGE AND POST END ON HEAVY-DUTY CRANKSHAFTS.

-

CRANKSHAFT GRINDING WITH THE NUMERIKA GH 1500 CORUNDUM GRINDING MACHINE

THE NUMERIKA GH1500 CYLINDRICAL grinding machine reliably produces thyssenkrupp‘s crankshafts. The user-friendly control system, a torsion-resistant machine bed, hydrostatic guides and grinding spindles with hydrostatic bearings ensure ideal corundum grinding results. The user-friendly control system offers the required input screens for grinding with corundum.

thyssenkrupp Forged Technologies operates 17 locations in 8 different countries and is part of the thyssenkrupp AG headquartered in Essen, Germany. In his 21 years at thyssenkrupp, Process Engineering Manager Jose Fernando Dias de Moraes has been actively involved in several grinding projects at the company‘s production sites worldwide. His experiences with ZEMA Zscelica Ltda during his career have been very positive and valuable.

Dias de Moraes has been at the site in Danville, IL for four years now. Together with six other engineers, he oversees four production lines. The NUMERIKA GH1500 grinds crankshafts in three-shift operation seven days a week. The line, which mainly produces crankshafts for heavy-duty trucks and construction machinery from around the world, will expand with an additional NUMERIKA GH1500 by the end of this year.

Diese Geschichte stammt aus der October 2020-Ausgabe von Manufacturing Today.

Abonnieren Sie Magzter GOLD, um auf Tausende kuratierter Premium-Geschichten und über 9.000 Zeitschriften und Zeitungen zuzugreifen.

Sie sind bereits Abonnent? Anmelden

WEITERE GESCHICHTEN VON Manufacturing Today

Manufacturing Today

THE OPEN AUTOMATION MOVEMENT

How Schneider Electric is powering India's industrial future with Open, Software-Defined Automation

10 mins

December 2025

Manufacturing Today

A look back and the road ahead

The year 2025 will be remembered as a period of recalibration for India's manufacturing sector. Far from a mere continuation of post-pandemic recovery, it was a year defined by the complex interplay of global economic headwinds, rapid technological adoption and a decisive domestic push towards self-reliance and sustainability. For an industry that forms the bedrock of the nation's economic ambition, 2025 was less about incremental growth and more about structural transformation, setting the stage for a more competitive and demanding 2026.

23 mins

December 2025

Manufacturing Today

The fifth dimension

How 5-Axis machining is redefining precision and agility in manufacturing.

6 mins

December 2025

Manufacturing Today

Axirium Aerospace raises $3.5M to boost precision manufacturing

The investment will expand Axirium's first manufacturing facility.

1 min

December 2025

Manufacturing Today

Flying Wedge, AP govt to build India's first combat UAV hub

The project by Flying Wedge positions Andhra Pradesh as a strategic hub for next-generation defence and aerospace manufacturing.

1 min

December 2025

Manufacturing Today

Monolithisch India acquires Mineral India

Mineral India reported a turnover of Rs 49.39 crore and a PAT of Rs 6.30 crore, with a robust customer base in Chhattisgarh and central India.

1 min

December 2025

Manufacturing Today

Smart. Mobile. Made.

India's mobile and accessories industry is rapidly transforming into a high-tech, sustainable, and self-reliant manufacturing ecosystem driven by innovation, automation, and local value creation.

5 mins

December 2025

Manufacturing Today

Karnataka to build 200-acre semiconductor park in new KWIN City

Karnataka announces a 200-acre semiconductor park within the upcoming KWIN City, aiming to strengthen India's advanced manufacturing and deep-tech ecosystem

1 mins

December 2025

Manufacturing Today

Driving Efficiency & Sustainability Through Advanced Power Transmission Systems

In today's industrial landscape, efficiency and sustainability are no longer optional; they're essential. PowerBuild, with its decades of engineering excellence, is at the forefront of this transformation. Through its advanced range of power transmission products, the company is actively helping industries minimize energy consumption, extend machine lifespans, and transition toward greener manufacturing practices. PowerBuild's entire gearbox and geared motor portfolio is engineered with energy optimization at its core. Whether it's the Series M Helical Inline Geared Motors, known for their compact design and high efficiency, or the Series K Helical Bevel Geared Motors, offering torque up to 50,000 Nm with minimal energy loss, each product is built to maximize output while reducing unnecessary power draw. These solutions are precision-designed to minimize friction, vibration, and wear three major contributors to energy inefficiency and mechanical failure.

1 mins

December 2025

Manufacturing Today

Is your facility ready for 24/7 automation?

Lights-out manufacturing is rapidly emerging as the future of Indian industry, but its success hinges on blending advanced automation with strong digital infrastructure, cybersecurity, and human adaptability.

6 mins

December 2025

Translate

Change font size