Sturm, Ruger & Company introduced the M77 bolt-action rifle in 1968, a design refined by Jim Sullivan during his three year stint with the company. The M77 is often described as a modernized Mauser ’98, including a two-lug bolt with a claw extractor, though several revisions were introduced. Legendary stock maker Lenard Brownell was tapped to create the classically lined stock of straight-grained walnut. Bill Ruger made the decision to create receivers through investment casting instead of more costly traditional forging methods. Sullivan’s bolt design eliminated the Mauser blade-style ejector and replaced it with a simpler plunger-style version. The inherently-intuitive, two-position tang safety (which locks the bolt when engaged), crisp, user-adjustable trigger system and angled action screw were also new.

The latter is significant and another example of Ruger’s genius for streamlining mass production. The Mauser’s forward action screw draws the receiver straight down into the stock, while the M77’s angled action screw pulls the action both down and rearward. The traditional vertical configuration used on Mauser designs pulls the receiver flat straight down behind the recoil lug and into the wood. This requires precise in letting to assure the stock doesn’t split in that area, a task that can add an hour of handwork while assembling a rifle, increasing labor costs. The M77 is inletted to close, but not precise, specifications and the angled screw is used to pull wood and metal together to produce a close-fitted, well-bedded mating while minimizing labor costs.

This story is from the October - November 2020 edition of Handloader.

Start your 7-day Magzter GOLD free trial to access thousands of curated premium stories, and 8,500+ magazines and newspapers.

Already a subscriber ? Sign In

This story is from the October - November 2020 edition of Handloader.

Start your 7-day Magzter GOLD free trial to access thousands of curated premium stories, and 8,500+ magazines and newspapers.

Already a subscriber? Sign In

OEHLER's New System 89 Chronograph

Measuring Bullet Performance Downrange

The Problem with Low Pressure Loads

Bullets & Brass

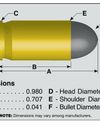

Measurements for Rifle Handloading

Handy Techniques for Accurate Ammunition

THE BRASS RING

In Range

Semi-custom Bullet Moulds

Mike's Shoot in' Shack

REVISITING THE 6.5 -06 A-SQUARE

Loading New Bullets and Powders

Cimarron Stainless Frontier .45 Colt

From the Hip

9x18mm Makarov

Cartridge Board

Alliant 20/28

Propellant Profiles

.224 Clark

Wildcat Cartridges