With all the attention on new bullets and powders, the focus has gotten away from what is arguably the most critical component of a handload. The brass case offers so many opportunities for improving performance, it deserves attention.

This story is from the April - May 2020 edition of Handloader.

Start your 7-day Magzter GOLD free trial to access thousands of curated premium stories, and 8,500+ magazines and newspapers.

Already a subscriber ? Sign In

This story is from the April - May 2020 edition of Handloader.

Start your 7-day Magzter GOLD free trial to access thousands of curated premium stories, and 8,500+ magazines and newspapers.

Already a subscriber? Sign In

OEHLER's New System 89 Chronograph

Measuring Bullet Performance Downrange

The Problem with Low Pressure Loads

Bullets & Brass

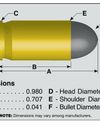

Measurements for Rifle Handloading

Handy Techniques for Accurate Ammunition

THE BRASS RING

In Range

Semi-custom Bullet Moulds

Mike's Shoot in' Shack

REVISITING THE 6.5 -06 A-SQUARE

Loading New Bullets and Powders

Cimarron Stainless Frontier .45 Colt

From the Hip

9x18mm Makarov

Cartridge Board

Alliant 20/28

Propellant Profiles

.224 Clark

Wildcat Cartridges