There is nothing like the feeling of gazing on a new box of shining bullets that are perfectly formed with polished surfaces unblemished by human touch. Handloaders are almost giddy with anticipation of how the exquisite gems will perform, and can hardly wait to pull a loaded round out of a seating die to admire the full cartridge. Suddenly, the future is marred by the sight of an ugly scratch or indent plowed around the tip!

The first thought comes in four letters and the next ones are not good. Will the indent affect bullet flight? Will it degrade ballistic coefficient? Could it cause broken petals on expansion? When recovered from the big downer, thoughts go to why it happened and how to prevent it.

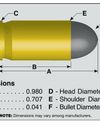

One cause of the ring could be lack of an inside case mouth chamfer. This causes a lot of resistance in starting a bullet base into a case mouth, often scraping off some bullet jacket as well. Remember to chamfer new brass and even once-fired factory cases. One exception is Nosler brass, because it comes already chamfered.

The cutting angle on your chamfer tool could be too abrupt for your bullet, again requiring too much force to start it into a case neck. Chamfering tools come with different cutting angles. One is for conventional bullets and another cuts a shallower angle for starting VLD-type bullets.

This story is from the December - January 2020 edition of Handloader.

Start your 7-day Magzter GOLD free trial to access thousands of curated premium stories, and 8,500+ magazines and newspapers.

Already a subscriber ? Sign In

This story is from the December - January 2020 edition of Handloader.

Start your 7-day Magzter GOLD free trial to access thousands of curated premium stories, and 8,500+ magazines and newspapers.

Already a subscriber? Sign In

OEHLER's New System 89 Chronograph

Measuring Bullet Performance Downrange

The Problem with Low Pressure Loads

Bullets & Brass

Measurements for Rifle Handloading

Handy Techniques for Accurate Ammunition

THE BRASS RING

In Range

Semi-custom Bullet Moulds

Mike's Shoot in' Shack

REVISITING THE 6.5 -06 A-SQUARE

Loading New Bullets and Powders

Cimarron Stainless Frontier .45 Colt

From the Hip

9x18mm Makarov

Cartridge Board

Alliant 20/28

Propellant Profiles

.224 Clark

Wildcat Cartridges