As a “professional woodworker” I often get asked what’s the best bang-for-the-buck tool by people getting into this craft. My response is always to ask if they have a good quality block plane. I know, it’s not the big, awesome aircraft carrier like jointer plane. Nor is it the smoothing plane that makes sexy, fluffy shavings. But when it comes down to it, I feel like you get the most mileage out of a block plane, so that’s where I suggest you start.

Basic Design

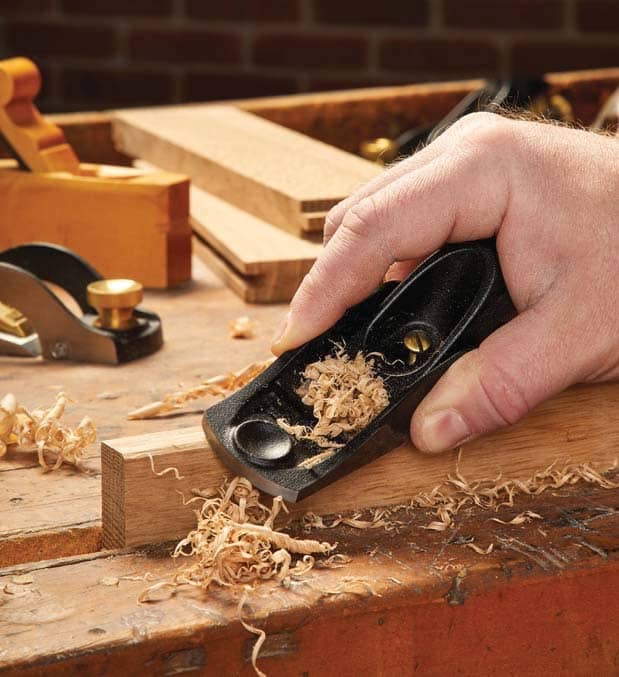

Before we get into why I feel like a block plane is the most versatile plane in your shop, let’s talk about the physical traits of a block plane. In general terms, a block plane is a small plane (less than 7 long) that has a low blade angle, and the cutter is bevel-up. Usually, they will be between 11/2 to 2 wide. These can be coined as apron planes, standard angle blocks, English miter planes, low-angle block planes, pocket planes, or anything in between.

Now, I’m saying this in general terms because there is some debate on if the design, use, or the application makes it a block plane. But for the purpose of this article, we’ll focus on the smaller, bevel-up planes. (I do have one plane that technically isn’t a block plane, but it identifies as a block plane— we’ll talk about that later.)

This story is from the August 2020 edition of Popular Woodworking.

Start your 7-day Magzter GOLD free trial to access thousands of curated premium stories, and 8,500+ magazines and newspapers.

Already a subscriber ? Sign In

This story is from the August 2020 edition of Popular Woodworking.

Start your 7-day Magzter GOLD free trial to access thousands of curated premium stories, and 8,500+ magazines and newspapers.

Already a subscriber? Sign In

Woodworking Techniques Restoring an Antique Rocking Chair

Bring new life to a tired antique. Here are my steps to restoring an old rocking chair

CRAFTING MAGIC: Making a Drawer Box

One of magic's oldest box tricks.

Laminated Coping Saw

This project brings together a diverse set of skills including epoxy work, bent lamination, metalworking, turning, and riveting

Mid-Century Media Console

This Mid-Century table is a great way to blend woodworking with modern materials

Tools 101 Calling all Dust Extractors

We take a look at eight dust extractors to see which ones stand out and which ones suck the most

SawStop Compact Table Saw

Most woodworkers are familiar now with the SawStop line of table saws

Grizzly Electric Sawmill

As a sawmill owner, I cut lumber for a variety of outlets. Most, I cut for myself

Veneered and Dovetailed Box

A box like this one is the perfect way to polish your hand tool skills and play with new techniques.

Mid-Mod Sideboard

All the flavors of walnut shine in this versatile storage and serving piece.

Limbert Style #357 Bookcase

Traditional construction techniques make this mediumsized bookcase a real gem.