Michael Preysman has come to China on a warm day in October to confront a young executive whose family owns the Dongguan factory that makes his popular backpacks. Preysman is the fast-talking founder and chief executive officer of Everlane, the five-year-old online clothing company committed to, and capitalizing on, “radical transparency” about where its shirts, sweaters, T-shirts, pants, coats, shoes, and bags are made and how much they cost to make. Its influence is greater than its size suggests: Everlane has been called “the Internet’s smartest clothing brand” (Fader) and the next J.Crew (Racked). “We want the look of Céline and the ethics of Patagonia,” Preysman says.

In May 2014 the Dongguan factory shipped almost 1,000 Everlane backpacks with the strap buckles on backward, and they went out to customers without anyone noticing. The company had to recall the bags. Preysman is also concerned about the factory’s low score on a recent audit of its working conditions.

“I had to tell him he’s our No. 1 problem,” Preysman says shortly after a meeting with the executive. “We’re his smallest client, so I thought maybe he just doesn’t care,” he adds. “But he says he wants to keep our business.” Preysman is visiting two other factories on this trip; Everlane will select one to take over some—or all— of its bag production if it doesn’t keep all its business in Dongguan.

This story is from the December 07 - 13, 2015 edition of Bloomberg Businessweek.

Start your 7-day Magzter GOLD free trial to access thousands of curated premium stories, and 8,500+ magazines and newspapers.

Already a subscriber ? Sign In

This story is from the December 07 - 13, 2015 edition of Bloomberg Businessweek.

Start your 7-day Magzter GOLD free trial to access thousands of curated premium stories, and 8,500+ magazines and newspapers.

Already a subscriber? Sign In

Instagram's Founders Say It's Time for a New Social App

The rise of AI and the fall of Twitter could create opportunities for upstarts

Running in Circles

A subscription running shoe program aims to fight footwear waste

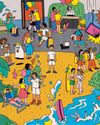

What I Learned Working at a Hawaiien Mega-Resort

Nine wild secrets from the staff at Turtle Bay, who have to manage everyone from haughty honeymooners to go-go-dancing golfers.

How Noma Will Blossom In Kyoto

The best restaurant in the world just began its second pop-up in Japan. Here's what's cooking

The Last-Mover Problem

A startup called Sennder is trying to bring an extremely tech-resistant industry into the age of apps

Tick Tock, TikTok

The US thinks the Chinese-owned social media app is a major national security risk. TikTok is running out of ways to avoid a ban

Cleaner Clothing Dye, Made From Bacteria

A UK company produces colors with less water than conventional methods and no toxic chemicals

Pumping Heat in Hamburg

The German port city plans to store hot water underground and bring it up to heat homes in the winter

Sustainability: Calamari's Climate Edge

Squid's ability to flourish in warmer waters makes it fitting for a diet for the changing environment

New Money, New Problems

In Naples, an influx of wealthy is displacing out-of-towners lower-income workers